Otto Wichterle Centre of Polymer Materials and Technologies

Innovation centre of the Institute of Macromolecular Chemistry, Academy of Sciences of the Czech Republic

contacts

contacts

Dr. Jiří Kotekhead of OW-CPMT

+420 296 809 316

cpmtow(a)imc.cas.cz

www.imc.cas.cz/cpmtow/

OW-CPMT

IMC CAS CR

Heyrovského nám.2

162 06 Praha 6

Chemical degradation and thermodynamics

head:

Hynek Beneš

contact: ![]() +420 296 809 313,

+420 296 809 313,

![]() benesh(a)imc.cas.cz

benesh(a)imc.cas.cz

Degradation means the change of structure and properties of polymers caused by decomposition reactions of polymers. Basic research is focused on understanding of degradation behaviour of polymers due to various external factors. We study mechanisms of photolytic, photo-oxidative, thermo-oxidative and chemical degradation of various types of polymer materials.

In application research we try to practically use acquired experience for the possibility of stabilization of polymer products to prolong their durability or on the contrary to develop more easily degradable products, e.g. biodegradable plastics for short-term use. The knowledge of mechanisms of chemical degradation of polymers is used for the development of new recycling technologies for plastic components of municipal, technological or industrial wastes so that they could be reused for production of new materials.

Applied thermodynamics in the field of polymer materials, which investigate physical and chemical processes connected with heat exchange, are based especially on calorimetric measurements. These measurements enable not only the obtaining of thermodynamic data on developed recycling procedures (e.g. efficiency of compatibilization of components of mixed plastic waste), but they are also a valuable information source for detailed thermodynamic and kinetic description of phase changes (e.g. crystallization) of studied polymer materials and obtaining of their material parameters such as temperature of glass transition Tg or thermal capacity cp.

For more detailed information on research work see IMC websites Department of polymer processing.

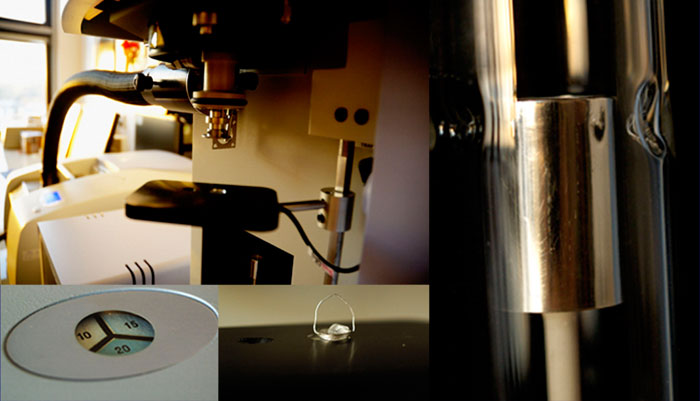

Equipment/methods

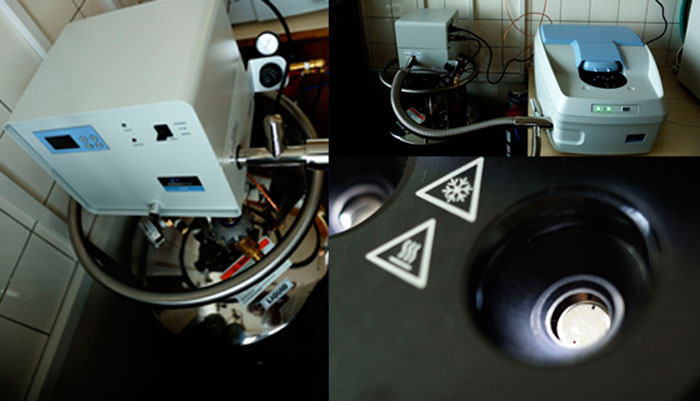

Differential scanning calorimetry (DSC):

- DSC calorimeter 8500 (PerkinElmer, USA) with liquid nitrogen cooling

- o temperature range: from -180°C to 750°C/li>

- o atmosphere: He, N2

- o heating and cooling rate: 0.01 – 750°C/min

- o temperature modulation mode (MT-DSC)

- o Hyper DSC mode (DSC with very fast scanning of temperature)

-

DSC calorimeter Pyris 1 (PerkinElmer, USA) with liquid nitrogen cooling

- temperature range: from -180°C to 750°C

- o atmosphere: He

- o heating and cooling rate: 0.01 – 750°C/min

- o temperature modulation mode (MT-DSC)

- DSC calorimeter DSC 7 (PerkinElmer, USA)

- o temperature range: from -30°C to 725°C

- atmosphere: N2, air, O2

- characterization of polymer materials using differential scanning calorimetry (DSC) according to ISO 11357

- characterization of polymer materials (polymers, copolymers, mixtures, composite))

- assessment of effectiveness of compatibilization of polymer mixtures

- determination of oxidation index, oxidation period

- determination of melting and crystallization heat, reaction heat, degree of conversion and temperature of glass transition

- determination of specific heat capacity (cp)

TG-IR analysis:

-

Thermogravimetric analyser Pyris 1 TGA (PerkinElmer, USA)

- o temperature range: 25°C – 1000°C

- o atmosphere: N2, air

- o heating rate: 0.1 – 200°C/min

- Infrared spectrometer Spectrum 100T FT-IR (PerkinElmer, USA) for on-line analysis of developed gases

- online connection with TG analyser using heated tube (interface TL-8000)

- o flow gas cell

- FR-DTGS detektor

- automatic correction for removal of influence of H2O a CO2 present in the atmosphere

foto Hynek Beneš & archiv ÚMCH AV ČR

design -4logC+ © 2012-2014