Posters

1 2 3 4 5 6 7 8

P01

NOVEL HYDROPHILIC/HYDROPHOBIC POLYMER BLENDS AS MEMBRANE MATERIALS

Jun Qiu, K.-V. Peinemann

GKSS Forschungszentrum GmbH, 21502 Geesthacht, Germany

Two phase interpenetrating polymeric structures may show unexpected

transport properties, which cannot be predicted easily by the pure

phases. A famous example of a two phase interpenetrating membrane

material is DuPont's Nafion, which consists of a perfluorcarbon matrix

containing a second continuous phase comprised of sulfonated

perfluorocarbon. The hydrophobic perfluorocarbon phase prevents

excessive swelling of the hydrophilic sulfonic acid phase. This leads

to unusual high cation permselectivity. In this lecture preparation

methods and transport properties of new blends of hydrophilic and

hydrophobic polymers are presented. These blends can usually not been

prepared by solution casting, because in most cases no common solvents

exist for the two polymers. We solved this problem by a " Trojan Horse"

approach. The hydrophilic polymer was transferred by a simple chemical

modification into a hydrophobic polymer, which subsequently could be

mixed with a second hydrophobic polymer. After obtaining the

solvent-free blend the chemically modified hydrophobic polymer (the

Trojan Horse) was changed back into the original hydrophilic polymer.

By this method unique blends could be prepared.

Transport properties for gaseous and liquid mixtures will be discussed.

P02

IONOMER CHARACTERIZATION FOR USE IN FUEL CELLS

F. J. Fernández-Carretero,a* V. Compañ,a, E. Riande,b R. Díaz-Calleja,a A. Quijano,c

a Departamento de Termodinámica Aplicada. ETSII. Universidad Politécnica de Valencia. 46020, Valencia. Spain

b Instituto de Ciencia y Tecnología de Polímeros (CSIC), 28006, Madrid. Spain

c Instituto de Tecnología Eléctrica, 46980, Valencia. Spain

*fraferc4@etsii.upv.es

INTRODUCTION

Ionic conductive solid materials are good electrolyte candidates for

fuel cells, electrodialyzers, batteries, sensors, etc. The growing

interest in the development of fuel cells and batteries has prompted a

flourishing research in the preparation of ionic organic solid

conductors based on polymers due to the excellent mechanical properties

and easy processing of these materials. From a practical point of view,

ion-exchange membranes displaying good performance for a variety of

applications should exhibit high ionic selectivity, good ionic

conductance, low permeability to free diffusion of electrolytes and low

electroosmosis, as well as chemical stability, high mechanical

resistance, high flexibility and good dimensional stability at the

working conditions. Moreover, fuel diffusion across membranes should be

severely hindered. Some of these properties are incompatible and

therefore it is necessary to reach a balance among them in order to

design membranes with optimum performance, .

The deleterious permeation effect of perfluorocarbon commercial

membranes together with their still high cost and negative

environmental effects have promoted the search for alternatives to

these materials.

MEMBRANE PREPARATION

Semicrystalline polypropylene (Repsol) and EPDM Vistalon 9500

(Exxon Chemical, France), a polyolefinic terpolymer containing 60 wt %

of ethylene, 29 wt % of propylene, and 11 wt % of

5-ethylidine-2-norbornene, were used. The 5-ethylidine-2-norbornene

units were sulfonated using the procedure developed by Makowski et. al.

In brief, acetic anhydride and concentrated sulphuric acid were slowly

added to a solution of EPDM in n-hexane under vigorous stirring. The

temperature of the solution was not allowed to exceed 0 ºC and the

reaction was stopped after 30 min by adding alcohol to the reaction

medium. The acidic form of the sulfonated polymer was further separated

by adding deionized water to the reaction medium and flashing off the

hydrocarbon solvents. The polymer was washed several times with water

until neutral pH was obtained and dried at 100 ºC.

Two blends of sulfonated EPDM and polypropylene (PP) containing 0.10

(wt/wt) (ICTP1) and 0.20 (wt/wt) (ICTP2) of the latter component

respectively, were prepared in a Brabender torque rheometer using a

thermoplastic mixing chamber (type W60) of 75 cm3 of capacity, keeping the temperature in the preheating step at 453 K. The rotor speed was set at 55 rev min-1

and once the torque was constant the materials was sheared in the

chamber for about 10 min more to ensure good blending homogenization. A

small amount of butyl phthalate was used as plasticizer in the blending

process.

Membranes were prepared from the sulfonated blends by compression at

200 bars in a Collins Hydraulic press for about 20 min. During

compression the samples were kept at 200 ºC for 10 min and then cooled

down to room temperature without removing the pressure

A commercial Nafion 117 membrane manufactured by DuPont was used as

a referent to check the electrochemical performance of the membranes

prepared from sulfonated EPDM-polypropylene blends.

CHARACTERIZATION

Water uptake

Dry sulfonated membranes in the acidic (R-SO3H) form were

weighed and further immersed in distilled water. From time to time the

membranes were removed from water, superficially dried by gently

pressing between filter paper and weighed. This operation was repeated

until a constant weight was reached. From the weights of the dried and

wet membranes the water uptake was obtained, and the pertinent results

are shown in Table 1.

Ion-exchange capacity

The membranes were equilibrated in a 2 M HCl solution overnight. The

acidic membranes were further washed several times with distilled water

and then equilibrated with a 2 M sodium chloride solution. The protons

delivered after the ion-exchange reaction R-SO3H + Na+ →R-SO3Na + H+

took place were titrated with a 0.01 M sodium hydroxide solution. The

values of the ion-exchange capacity of the membranes used in this study

are collected in Table 1.

|

Membrane

|

Weight of the wet membrane (g)

|

Weight of the dry membrane (g)

|

Exchange capacity H+ (mol/kg of dry membrane)

|

Water uptake (%)

|

H+ (mol/kg of water in the membrane)

|

|

ICTP1

|

0.1170

|

0.0816

|

2.45

|

43.38

|

5.65

|

|

ICTP2

|

0.0939

|

0.0761

|

1.27

|

23.35

|

5.43

|

|

Nafion 117

|

0.1417

|

0.1180

|

1.35

|

20.09

|

6.70

|

Table 1 Water uptake and ionic exchange capacity

It can be seen that water uptake decreases in ICTP2 due to the

percent of EPDM is lower than in ICTP1 so there are less hydrophilic

groups (5-ethylidine-2-norbornene units). In this way, ionic exchange

capacity of ICTP2 is also low than ICTP1. Both membranes have suitable

values of the IEC for its use as ionic exchange membranes.

Transport Number

Transport numbers were determined according to the irreversible

processes thermodynamics to characterize the transport properties of

the membranes, , , , .

Experimental electrochemical potentials were measured in a cell with the following configuration:

Ag | AgCl | HCl solution (cL)| membrane | HCl solution (cR) | AgCl | Ag.

cL is fixed, 0,01M, while cR varies from 0,001 to 1.

The cell employed is made of Pyrex glass and the membrane was tightly campled between two compartments of 150 cm3

capacity. The electrodes were dipped into the cell and connected to a

multimeter HP 3441. The electromotive force was recorded with a PC that

took measures every 5 s. During the measurements, the cell solutions

were stirred to minimize polarization effects.

Experiments have been repeated changing HCl solutions for NaCl to

study the membrane behaviour when the size of the ion raises (H+ vs. Na+).

Results are shown in table 2, where one can see that near 1 transport numbers are obtained when working with H+ as a result of good ionic exchange properties. When using Na+ the increase in ion size results in a decrease of the transport numbers.

|

Steady state

|

|

|

medio

|

|

ICTP1 H+

|

0,9602

|

|

ICTP2 H+

|

0,9701

|

|

Nafion H+

|

0,9721

|

|

ICTP1 Na+

|

0,6830

|

|

ICTP2 Na+

|

0,7187

|

|

Nafion Na+

|

0,6751

|

Table 2 Membranes transport number

Electrical analysis

Proton conductivity was measured using impedance spectroscopy using

a dielectric spectrometer Novocontrol with Alpha analyzer and Quatro

temperature control. Samples were measured sandwiched in the liquid

sample cell BDS 1308 in distilled water to simulate 100% RH. Frequency range was from 10-2 to 106

Hz in isothermal conditions with amplitude of 1V.Conductivity has been

obtained from intersection with the real impedance axis in the high

frequency side of Nyquist and, using a second method, from the Bode

plots, obtaining conductivity when phase angle trends to 0 in the high

frequency area.

Fig. 1 ICTP1 Bode plot

Fig. 2 ICTP2 Nyquist Plot

Conductivities are shown in table 3,

|

|

ICTP1

|

ICTP2

|

Nafion 117

|

|

T(ºC)

|

(S/cm)

|

(S/cm)

|

(S/cm)

|

|

25

|

9,84E-04

|

7,25E-04

|

5,73E-03

|

|

50

|

8,17E-03

|

1,12E-03

|

8,98E-03

|

|

75

|

1,60E-02

|

2,01E-03

|

1,30E-02

|

|

90

|

8,35E-02

|

1,03E-02

|

1,16E-02

|

Table 3 Conductivities of the membranes

Conductivity is better in ICTP1; this was expected because ICTP1 has

the highest ionic exchange capacity. And there's an increase in the

conductivity when the temperature raises form 75 to 90ºC in the EPDM

membranes, while there's no raise in Nafion one's.

CONCLUSIONS

The comparison of the electrochemical properties of the ICTP1 and

ICTP2 membranes expressed in terms of the conductivity and proton

transport number with those of Nafion, suggests that the ICTP1 membrane

exhibits similar performance as the Nafion membrane.

However, to conclude whether the ICTP membranes could be used in

fuel cells would require to investigate their chemical and mechanical

stability at high temperatures.

ACKNOWLEDGEMENTS

This work was supported by the AVCT ( Generalitat Valenciana), CAM

(Comunidad Autónoma de Madrid) and the DGCYT through Grants

Grupos03/030, IMCITA2005/31, GR/MAT/0723/2004, and MAT2002-04042-C0-1,

respectively.

REFERENCES

Lakshminarayanaiah, N. Transport phenomena in membranes, Academic Press, London, 1969

Riande, E. Transport

phenomena in ion-exchange membranes, In Physics of electrolytes, Vol.

I, J. Hladik, ed., Academic Press, London, 1972; Chapter XI

Makowski, H.S., Plains, S., Lundberg, R.D., Block, J. U.S. Patent 1980, 4,184,988

J. Garrido, V. Compañ, V.M. Aguililla, S. Mafé. Electrochem. Acta 35 (1990) 4 705-709

J. Garrido, V. Compañ, M.L. López, D.G. Millar. J. Phys. Chem. B 101 (1997) 29 5740-5746

V. Compañ, T.S. Sorensen, A. Andrio, L. López, J. de Abajo. J. Memb. Sci. 123 (1997) 293-302

J. Garrido, V. Compañ, M.L. López. Curr. Top. Electrochem. 4 (1997) 115-126

J. Garrido, V. Compañ, M.L. López. Phys. Rev. E 64 (2001) 016122

A. Mokrini, M.A. Huneault, J. Pow. Sourc. 154 (2006) 51-58

R. Mohr, V. Kudela, J. Schauer, K. Richau, Deslination 147 (2002) 191-196

P 03

THERMAL BEHAVIOR AND MORPHOLOGY OF BIODEGRADABLE P(3HB)-BASED MEMBRANES

K. Wesslera, A.P.T. Pezzinb, S.H. Pezzinb

aCenter for Technological Sciences, Santa

Catarina State University - UDESC, Campus Universitário s/n, CP 631,

89223-100 Joinville-SC, Brazil (pezzin@joinville.udesc.br)

bUNIVILLE, CP 246, 89201-972 Joinville-SC, Brazil

Summary. The miscibility behavior and the morphology of

blends of poly(3-hydroxybutyrate), P(3HB), and polycaprolactone triol,

PCL-T, obtained by casting, were studied by differential scanning

calorimetry, thermogravimetric analysis, X-ray diffraction, infrared

spectroscopy and scanning electron microscopy. It was observed that

higher PCL-T ratios results in transparent, porous and flexible films.

Polyhydroxyalkanoates (PHAs) are thermoplastic polyesters made from

bacterial fermentation using renewable resources. The polymers are

produced as an intracellular storage polymer of carbon and energy under

various nutritional and environmental conditions (1). In the past two

decades, PHAs have been the focus of extensive research considering

their potential application as biocompatible and biodegradable

thermoplastics, due to their hydrolyzability in the human body as well

as in natural circumstances (2). The polymers of PHAs family more

extensively studied are poly(3-hydroxybutyrate), P(3HB) and the

copolymer poly(3-hydroxybutyrate)-co-(3-hydroxyvalerate) (P(3HB-co-3HV)).

P(3HB) can in principle be used in many applications, however, since

P(3HB) is highly crystalline and forms large spherulites and also has a

relatively high glass transition temperature in comparison with

polypropylene, polyethylene, etc., the material itself is regarded as

unacceptable brittle. Furthermore, P(3HB) suffers from an economic

disadvantage and limited processing temperatures. These drawbacks have

restricted the widespread application of P(3HB) (3). On the other hand,

poly(caprolactone - triol) (PCL-T) is a semi-crystalline polymer with

melting point around 30şC and glass transition temperature around

-68şC, being potentially interesting to be used in biomaterials (4).

Thus, it seems that PCL-T can be a good choice to plasticize P(3HB-co-3HV), maintaining its biodegradability and bioreabsorption properties.

Aiming the development of new ductile and porous biodegradable materials, blends of P(3HB) and P(3HB-co-3HV)

with polycaprolactone triol (PCL-T) in compositions varying from 100/0

to 70/30 P(3HB)/PCL-T (w/w), were obtained by casting. P(3HB) and P(3HB-co-3HV) used

in this research were kindly supplied by PHB Industrial S.A. and

purified prior to use by dissolution in chloroform and precipitation in

n-hexane. The number average molecular weight of P(3HB) and P(3HB-co-3HV), obtained by GPC, was around 3.0 x 105 g mol-1. PCL-T with 900 g mol-1 was purchased from Aldrich. Membranes

were obtained by casting from 1% chloroform solutions. The solution was

poured in a glass mold and placed in an evaporator system for 48 hours.

The films were completely dried in a vacuum oven at 60°C for 24 hours

and stored in a desiccator. The blends were further analyzed by X-ray

diffraction (XRD), differential scanning calorimetry (DSC),

thermogravimetric analysis (TGA), and scanning electron microscopy

(SEM).

The DSC data for P(3HB) blends are summarized in Table 1. It

was observed that the PCL-T melting temperatures did not change in all

compositions, while the P(3HB) melting temperatures decreases a little

when the PCL-T content is increased. It was also noted that the Tg of

PHB did not vary in function of the PCL-T content. The Tg of

the samples with low plasticizer content are badly defined, however

those from samples with higher PCL-T contents are best defined,

suggesting that the PCL-T addition diminishes the crystallinity of the

sample. These results suggest that the P(3HB)/PCL-T system is

immiscible. Indeed, FTIR analyses did not show evidences of hydrogen

bonds between the polymers. XRD analysis confirmed that the addition of

PCL-T to P(3HB) causes a decrease of ca. 30% on the crystallinity,

independently of the PCL-T content.

Table 1: DSC data (Tm) for PHB/PCL-T blends

|

Blendas P(3HB)/PCL-T

|

Tg PHB (şC)

|

Tm PCL-T (şC)

|

Tm P(3HB) (şC)

|

|

95/05

|

- 2.4

|

22.8

|

171.4

|

|

90/10

|

- 2.7

|

22.8

|

170.9

|

|

85/15

|

- 2.4

|

22.8

|

168.5

|

|

80/20

|

- 2.3

|

23.9

|

169.0

|

|

70/30

|

- 2.3

|

23.1

|

164.0

|

For P(3HB-co-3HV) blends, it was observed (Table 2) that the

glass transition temperatures decreased from 1,66şC to ca. -10şC with

the addition of 15 wt% of PCL-T. Further addition of PCL-T does not

modifies the Tg of P(3HB-co-3HV). It is also noticed that the melting temperatures of P(3HB-co-3HV)

and PCL-T decreases gradually as the PCL-T content is increased. The Tg

of the samples are best defined with higher PCL-T contents, suggesting

that the PCL-T addition decreases the crystallinity of the sample.

These results evidence a partial miscibility between PCL-T in P(3HB-co-3HV).

Table 2. DSC data (Tm) and (Tg) for P(3HB-co-3HV)/PCL-T 900 blends.

|

P(3HB-co-3HV)/

PCL-T

|

Tg (şC)

P(3HB-co-3HV)

|

Tm PCLT (şC)

|

Tc (şC)

P(3HB-co-3HV)

|

Tm (şC)

P(3HB-co-3HV)

|

|

100/0

|

1.66

|

-

|

53.36

|

172.0

|

|

90/10

|

-9.27

|

30.70

|

-

|

170.3

|

|

85/15

|

-10.43

|

20.04

|

53.19

|

168.5

|

|

80/20

|

-10.36

|

25.43

|

46.92

|

165.6

|

|

70/30

|

-10.18

|

24.20

|

50.32

|

164.0

|

Thermal degradation studies were carried out by thermogravimetric

methods, showing that the addition of PCL-T slightly decreases the

onset temperature of the P(3HB) degradation. SEM micrographs

revealed that higher PCL-T ratios result in very porous membranes. It

is also noted that the transparency of the membranes increases with the

PCL-T content, as well as the flexibility. These results suggest that

these materials have great potential to biomedical applications and

packings.

References

[1] P. D'haene, E.E. Remsen, J. Asrar. Macromolecules 32, 5229-5235 (1999).

[2] H. Tsuji, K. Suzuyoshi. Polym. Degrad. Stab. 75, 347-355 (2002).

[3] W. Chen, D.J. David, W.J. MacKnight, F.E. Karasz. Polymer 42, 8407-8414 (2001).

[4] 3. H.R. Lin, C.J. Kuo, Y.J. Lin. J.Cell.Plast. 39, 101 (2003).

P04

GRAFTING OF POLY(STYRENE-CO-MALEIC ANHYDRIDE) WITH POLY(ETHYLENE GLYCOL) FOR MEMBRANE PREPARATION

Diógenes Rojas, Peter F.W. Simón, Volker Abetz

GKSS Forschungzentrum Gesthaacht GmbH, Max Planck Str. 1, Gesthacht, D-21502 Germany

Diogenes.rojas/gkss.de

In the last year the use of copolymer membranes has emerged as a new

alternative and it has interested too many researchers. The main focus

of this area is to find the structure/property relation in polymers

materials and correlation with gas separation membranes properties. In

this way, the use of self-assembly polymer material which lead up to

obtain well-ordered structures due to the ease of accessing complex

structures with small features sizes (1-4).

The aims are to investigate the relation between the morphology and

the overall composition of Poly(Ethylene Glycol) (PEG) /

Poly(Styrene-co-Maleic Anhydride) (SMA) and their functionality, as

well as, to study the effect of the morphology on the membrane

properties (permeability, selectivity and diffusion). In our

experiments we use poly(styrene-co-maleic anhydride) and

poly(ethylene glycol). These copolymers are used to prepare the new

copolymers by esterification reaction and then all these products are

characterized by 1H-NMR, DSC, TGA and GPC. The dense

membrane method by casting is used to prepare films and then theses are

analyzed for contact angle, AFM, SEM, and finally are measured their

properties. Our first conclusion shows that due to the esterification

reaction it is possible to link and to increase PEG contents in the

matrix SMA which helps to reduce the glass transition temperature (Tg)

in the films. The contact angle showed that the membranes have more

hydrophilic behavior in comparison to the original matrix. And finally,

the functionality play particular role in the behavior of the membrane

properties.

References

- J.N Chan, G. D. Stucky, D. E. Morse, T.J. Deming, Nature 2000, 403, 289

- G.M. Whitesides. B. Grzybowski, Science 2002,295,2418

- Abetz, V.; Simon, P.W.F. Adv. Pol. Sci. 2005, 189,125

- S. H. Kim, M. J. Misner , T. P. Russell Adv. Mater. 2004, 16, 3 ,226

P05

6F6F AS GAS SEPARATION MEMBRANE. EFFECT OF THE FORMATION TEMPERATURE ON PERMSELECTIVITY

Roberto RecioVázquez1, Laura Palacio1, Pedro Prádanos1, Antonio Hernández1,

Ángel E. Lozano2, Ángel Marcos, José G. de la Campa2, Javier de Abajo2

1 Dpto. Física Aplicada, Universidad de Valladolid, Facultad de Ciencias, Real de Burgos s/n, 47071 Valladolid. Spain

2 Dpto. Química Macromolecular, Instituto de Polímeros, CSIC, Juan de la Cierva 3, 28006 Madrid. Spain

Over the last decades, polymeric membranes have proven to operate

successfully in industrial gas separations. To obtain membranes that

combine high permeability and high selectivity together with thermal

stability, new polymers, high added value materials, so-called

high-performance polymers, were developed like polyimide (PI). Several

aromatic polyimides as 6F6F have shown promising properties when

separating gas mixtures like O2/N2 and CO2/CH4.

In addition, a inverse relationship between permeability and

selectivity is observed, which fit a limit to the development of new

polymer structure that show a landmark in this field.

Nevertheless, membranes used for gas separation at the moment are of

solution-diffusion type polymeric membranes. One of the immediate

challenges facing membrane material design is achieving higher

permselectivity with equal or greater productivity compared to existing

materials. A high selectivity leads to a high purity of products and

allows a reduction in the number of operation steps and thus a cutback

in the needed membrane area. A high permeability involves a high

process velocity or productivity.

In this work, transport properties like permeability and selectivity

of gas separation membranes made from 6FDA-6FpDA with a

N,N-dimethylacetamide (DMAc) as solvent have been measured in a time

lag equipment. It has been shown that an increase in the temperature of

formation of the membrane leads to better selectivity versus

permeability compromise. This has been tested for O2/N2 and CO2/CH4 gas pairs.

An increase in the temperature of formation, to approach the boiling

temperature of the solvent, increases both the glass transition

temperature and the fractional free volume. These factors help to

explain the structural changes that allow simultaneous improvements of

permeability and selectivity.

P06

EFFECT OF FULLERENE ADDITIVES ON PERVAPORATION PROPERTIES OF POLY(PHENYLENE OXIDE) MEMBRANES

A.V. Penkovaa, A.M. Toikkaa, G.A. Polotskayab

a Dep. Chem. Thermodynamics & Kinetics, St.

Petersburg State University, University pr. 26, Petrodvoretz, St.

Petersburg, 198504, Russia (stasya84@nm.ru)

bInstitute of Macromolecular Compounds, Russian Academy of Sciences, St. Petersburg, Bolshoy pr. 31, 199004, Russia

The allotropic form of carbon known as fullerene exhibits unique

physico-chemical properties and can provide a possibility for

modification of polymer membrane. It has been shown that fullerene C60 improves polyphenylene oxide (PPO) transport properties in gas separation [1]. The combination of С60

and PPO gives a donor-acceptor complex that leads to increasing

membrane density and influence on gas transport properties. In the

present work, fullerene-containing PPO membranes are considered in

pervaporation processes. The effect of fullerene additives on PPO

transport properties is studied in the pervaporation of the reacting

mixture: ethanol - acetic acid - water - ethyl acetate in binary,

ternary, and quaternary combination of components. The shifting of the

esterification equilibrium:

C2H5OH + CH3COOH = Н2О + CH3COOC2H5 is one of the ways for maximizing yield of ethyl acetate in hybrid process involving pervaporation.

Homogeneous C60-PPO membranes containing up to 2 %wt C60 (~60 mm thick) were prepared by mixing PPO and C60 solutions in toluene, by casting the solution on a cellophane surface, and by drying at 40оС.

These membranes were studied in pervaporation of mixtures involving

ethanol, acetic acid, ethyl acetate, and water in different

combination. It was shown that permeate is enriched by ethyl acetate in

pervaporation of four-component mixture in equilibrium composition.

Acetic acid does not essentially permeate through all membranes under

study. High selectivity with respect to ethyl acetate was established

in pervaporation of two-component ethyl acetate/water mixtures. The use

of fullerene-containing membranes made it possible to increase

selectivity to 700 for 7% ethyl acetate in water (azeotrope). High

selectivity with respect to ethyl acetate is caused by hydrophobic

properties of our membranes.

Pervaporation properties of membrane depend on interactions between

components of the feed solution and the polymer of the membrane. To

estimate the interaction, equilibrium vapour sorption of ethanol,

acetic acid, water, and ethyl acetate was studied. Fullerene-containing

membranes show a better sorption capacity for ester, acid, and alcohol

than that of PPO membranes. Ethyl acetate exhibits the highest sorption

(the lowest value of χ), then acetic acid and ethanol come.

Water is absolutely inert to polymers under study. These results are in

good agreement with data on pervaporation.

Thus, it was established that fullerene as a component of the С60-PPO composition profoundly affects membrane properties.

Acknowledgement. This work was supported by Russian Foundation for Basic Research (grant 06-03-32493).

Reference

- G.Polotskaya, Yu.Biryulin, Z.Pientka, L.Brozova, M.Bleha,

Transport properties of fullerene - polyphenylene oxide homogeneous

membranes, Fullerenes, Nanotubes, and Carbon Nanostructures, 12(1) (2004) 387-391

polyaniline based responsive membrane

SUDIP RAY, NEIL R. EDMONDS AND ALLAN J. EASTEAL

Polymer Electronics Research Centre, Department of Chemistry, The

University of Auckland, Private Bag 92019, Auckland, New Zealand

(s.ray/auckland.ac.nz)

Responsive or 'smart' polymer materials are functional, structured

systems that show selective response to external (environmental)

conditions, such as temperature, light, pH, stress, strain, electric or

magnetic field. Polyaniline (PANI) has been investigated as a potential

membrane material for gas separation, due to its controllable

electrical conductivity, environmental stability and interesting redox

properties associated with the chain nitrogens. The present work is

designed to fabricate PANI based responsive membranes in different

ways. One of the key problems related to the application of PANI,

however, is its poor processability. The most promising approach to

this problem is the preparation of PANI blends with processable

thermoplastic polymers. Thus, solution and melt blending methods were

applied with polyvinylidene fluoride (PVDF) and/or polymethyl

methacrylate (PMMA) as the blending component(s) or as the support

material(s).

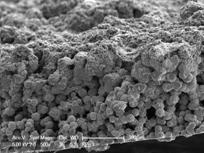

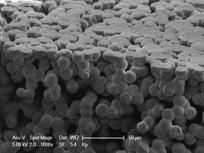

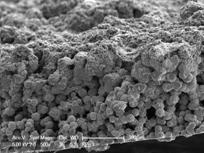

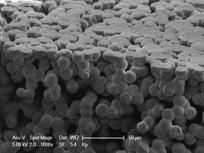

|  |

|

FIG. 1: SEM images of (a) porous PVDF as the support material and | (b) in-situ polymerized PANI over porous PVDF support.

|